Verborg Engineering B.V.

Your supplier for top-quality special purpose machinery.

With decades of hands-on experience, Verborg Engineering stands as a top-tier specialist in engineering and crafting custom machinery. Our focus has naturally evolved, with a strong niche in developing automated solutions for tasks like industrial packaging and leak testing.

Beyond designing and manufacturing new special purpose machinery, we offer spare parts and leverage our expertise to refurbish, modify, and enhance existing equipment. At Verborg Engineering, we're not just experts in machines; we're your partners in sustainable industrial solutions.

Go to projects:

(Click on any picture for more info)

A wide spectrum of processes and applications

Verborg Engineering B.V. stands at the forefront of engineering excellence, offering a comprehensive range of processes and applications designed to cater to diverse industrial needs. Our capabilities encompass a wide spectrum:

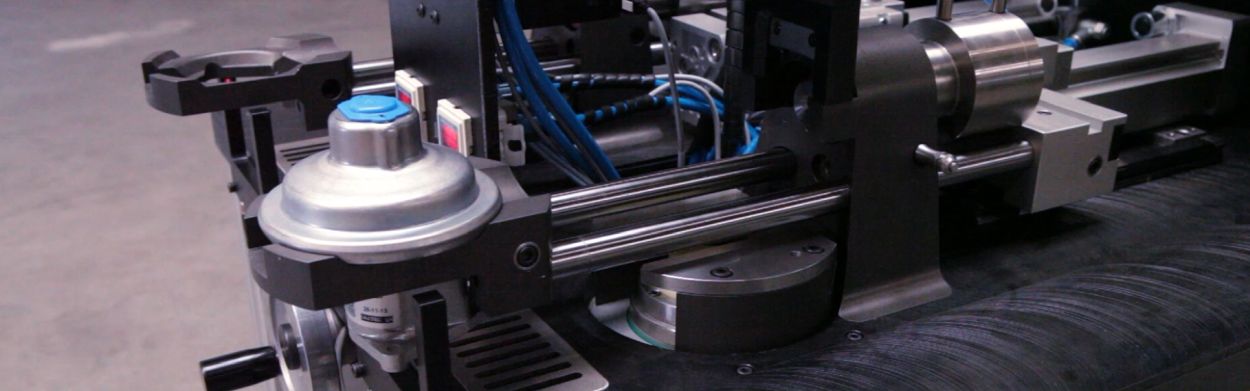

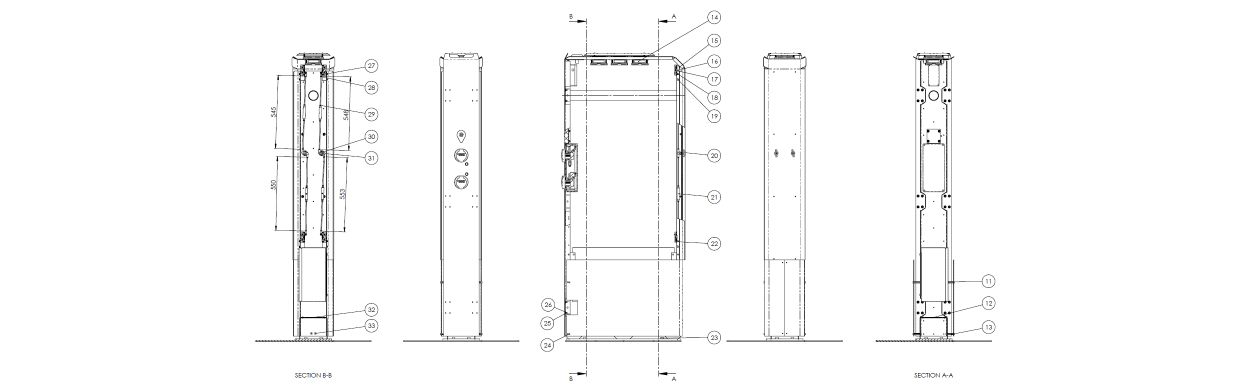

From the precision of automated leak testing systems to the seamless efficiency of assembly lines, we ensure optimal performance at every stage of production. Our seaming machinery is engineered to create impeccable seams, while our precurling machinery guarantees meticulous shaping. Riveting machinery provides robust connections, and our pick & place units offer agile and precise handling.

In the realm of precision, our measuring and calibration machinery ensures accuracy down to the finest detail. Our loading systems have been meticulously crafted to seamlessly integrate with, for example, our pressing and stamping processes. Meanwhile, our automatic screwing machinery streamlines assembly, and our dosing machines and dispensers provide accurate material distribution.

Moreover, we don't just create new solutions; we breathe new life into existing production machinery and lines through our revision, modernization, and maintenance services.

Our website proudly showcases a rich portfolio of projects, each a testament to our versatile skill set and expertise.

Understanding that each project has its unique requirements, we encourage you to reach out and contact us. Your specific challenges and needs are an opportunity for us to show what we can do, and we are confident that we can provide innovative solutions that align perfectly with your goals.